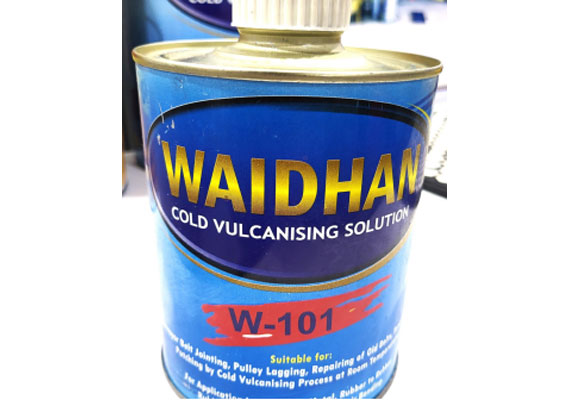

Cold Vulcanising Solution

W101 is a specially formulated rubber-based adhesive used in applications of bonding rubber to: rubber, metal, wood and many other materials. It has been formulated with solvents of low toxicity to produce an improved adhesion with lower health risks. When used in conjunction with Waidhan hardener, it provides excellent results in all rubber bonding applications. It is especially suitable for belt splicing, rubber lining, and pulley lagging. Our Cold Vulcanizing solution is available in 1ltr. and 5 Itr. packing.

Splicing Kit For Steel Cord Belts

We are into manufacturing of splicing kit for steel cord belts (upto ST 4000) and following jointing materials:

- Hot vulcanising solution

- Insulation compound

- Cover compound

- Tie gum (bonder rubber strips)

Fire resistant grade and various other grades are manufactured by us as per customers specific requirements.

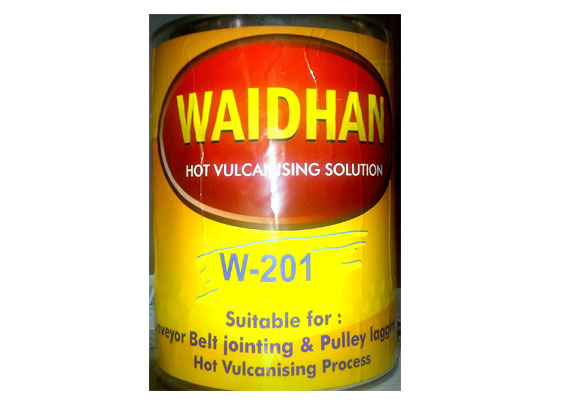

Hot Vulcanising Solution

Our hot solution is a liquid vulcanizing agent suitable for rubber bonding purposes. It can be used for belt splicing, pulley lagging, rubber lining and general hot rubber bonding. Special agents are added to enhance bond strength and improve ozone resistance. It is suitable in a press or autoclave bonding application and in general rubber moulding.

Insulation and Cover Compound

Our insulation and cover compounds provide the ultimate protection to the belt carcass so as to realize a lower cost-per-ton conveyed and also reducing overall maintenance cost. Our innovative compounds provide protection and performance even in the toughest applications.

Our manufacturing process is vertically integrated and unique to the conveyor belt industry. Backed by extensive research and testing facilities, we have cover compounds to meet the rigorous requirements. We have our own mixing facilities which provide raw materials used in making cover compounds, giving us more control over the quality of the product at every step.

Ceramic Pulley Lagging Sheets

Ceramic Pulley lagging is the most effective method of reducing the risk of slippage of conveyor belts. Waidhan group manufactures ceramic lagging sheets with high alumina (92%) ceramic tiles and CN bonding layer for general, industrial and mining purpose application.

| Model | Width (mm) | Length (mm) | Thickness (mm) | Ceramic Coverage |

|---|---|---|---|---|

| CL- 385 | 385mm | 4320mm | 13, 16, 20 | 46% (1150 Tiles per sqm.) |

| CL- 500 | 500mm | 2500mm | 13, 16, 20 | 30% (750 Tiles per sqm.) |

| CL- 445 (L) | 445mm | 550mm | 13, 16, 20 | 32% (800 Tiles per sqm.) |

| CL- 445 (H) | 445mm | 550mm | 13, 16, 20 | 51% (1280 Tiles per sqm.) |

Diamond Grooved Lagging Sheets

Waidhan group manufactures a comprehensive range of diamond and plain rubber lagging sheets for general, industrial and mining applications. We manufacture both small and large diamond profile pulley lagging.

Constructional Features

- Width: Upto 1650mm

- Length: Upto 20 metres in single length

- Thickness: 8mm to 25mm

- Comes with coloured bonding layer

Diamond grooved lagging sheets are ideal for driven pulleys with high tensions and belt ratings. They are press cured using high temperature and pressure thus proving to give significantly longer life.