Impact Pads

Waidhan group impact pads are designed for loading points of conveyor belts, where a combination of high energy absorption and low friction is needed. Due to ease of installation, these impact pads replace the conveyor rollers, which eventually break or seize and act like a brake. They provide greater belt support area thereby increasing impact absorption and reducing impact on the belt.

The top cover is made of an UHMWPE (ultra high molecular weight polyethylene), which gives these impact pads a very low friction and high we are resistant top surface. The middle portion is of high-quality rubber having high resilience, which acts as a shock absorber at the loading zones of conveyors. These impact pads are manufactured with an aluminium T-type fixing system for easy installation.

Support Frame :

Support frames are designed to suit a wide range of applications for impact pad. These heavy duty/sturdy pads are fixed over an equally robust heavy duty bolted type adjustable support frame to absorb high impact load.

| Width (mm) | Length (mm) | Thickness (mm) |

|---|---|---|

| 100mm | 500mm- 1500mm | 50-100mm |

| Rows of Pad Required at Each Loading Point | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Belt width (mm) | 600/650 | 750/800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 |

| No. of rows | 6 | 7 | 9 | 10 | 12 | 14 | 15 | 17 | 19 | 20 |

Skirting Rubber

We manufacture a complete line of skirtboard products. Skirting rubber is a general purpose rubber used mainly in material handling industry and is common to every conveyor application and paramount in the prevention of spillage at material loading points. This product is designed for use as conveyor skirtboard or belt wiper. It is made of black natural rubber & designed to be used as conveyor skirting or similar application. It is available in various thickness and widths depending upon customers requirements.

WEI also manufacture double lip skirt rubber. This product is effective for fine dust and provides double dust protection compared to conventional skirt rubber. It is supplied with Standard fixing clamps.

Chute Liner

Impact of rocks and other heavy materials can greatly reduce the lifetime of feed hoppers. Our wear products have been providing heavy duty wear protection in the mining industry since years. These wear products not only protect against wear but also serve as impact-dampers and prevent any damage to hoppers.

Feed hoppers are exposed to heavy stress due to continuous operation of crushing, cutting, abrasion and impact of rocks and other particles. The wear strength and elasticity of rubber generate valuable benefits during the entire working cycle. Industrial activities unavoidably result in wear. Wear costs money, often lots of money. That is why it pays to tackle wear with wear resistant rubber and cut costs in nearly every application from discharge and storage chutes, to hoppers.

Plain steel backed wear rubber plates are excellent wear lining for truck boxes, feeders, chutes, hoppers, bins, and other applications subject to wear and noise. It can easily be installed with a wide range of secure and reliable fastening methods.

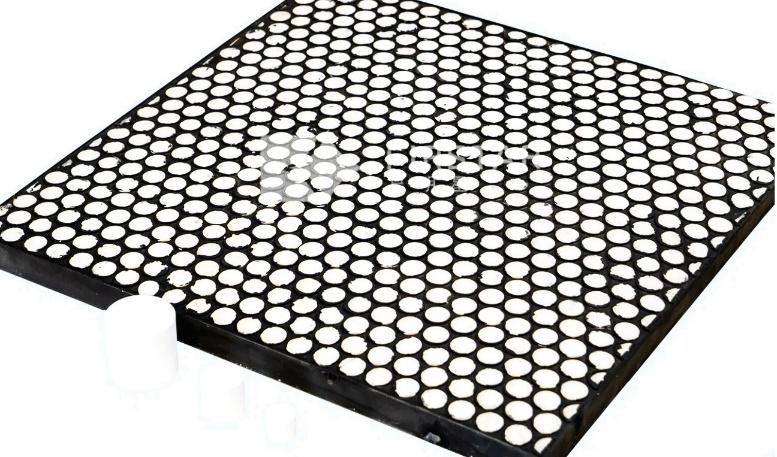

Ceramic Wear Resistant Liners Pads

Our ceramic wear pads exploits the high wear resistance of high alumina (92%) ceramic tiles and is especially suited for applications such as fine abrasive sliding particles and high-speed wet slurry. Waidhan groups ceramic wear pads are supplied with special CN bonding layer for very good adhesion to the metal or rubber surface. Metal backed liners are also available.

These liners come with cylinder, hexagonal or square tiles for various applications.

| Width {mm) | Length (mm) | Thickness (mm) | Thickness of Ceramic | Backing/Fixing |

|---|---|---|---|---|

| 500mm | 500mm | 8 | 5mm | CN Bonding Layer |

| 500mm | 500mm | 12 | 8mm | CN Bonding Layer |

| 500mm | 500mm | 20 | 12mm | Metal Backed |

| 500mm | 500mm | 30 | 15/20mm | Metal Backed |

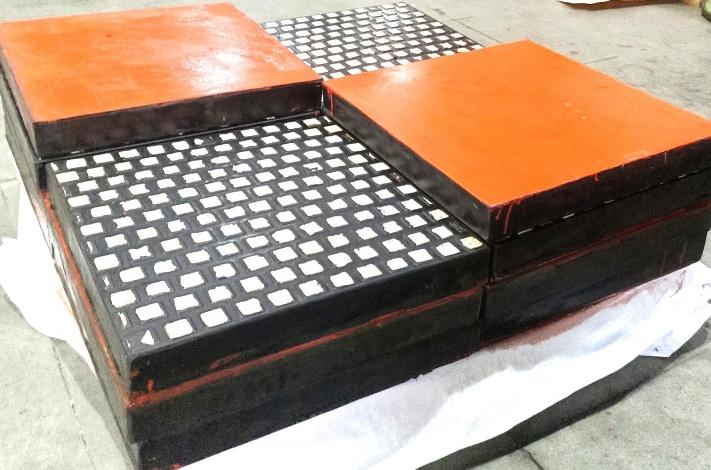

Rubber Blocks/Pads

Waidhan group manufactures a complete line of premium grade rubber blocks/pads for varied applications. These rubber blocks have been providing heavy duty wear protection in the material handling industry for years. They not only protect against wear but also serve as impact-dampers and prevent damage to wagon tipplers. We are manufacturing wagon tippler rubber pads for wagon tipplers installed at coal handling plants in thermal power plants, cement plants, coal mining etc. for automated unloading of railway wagons.

The quality of rubber blocks is excellent and have very good life. These rubber blocks are supplied with or without steel insert plate as per requirement of the customer. It can easily be installed with a wide range of secure and reliable fastening methods.

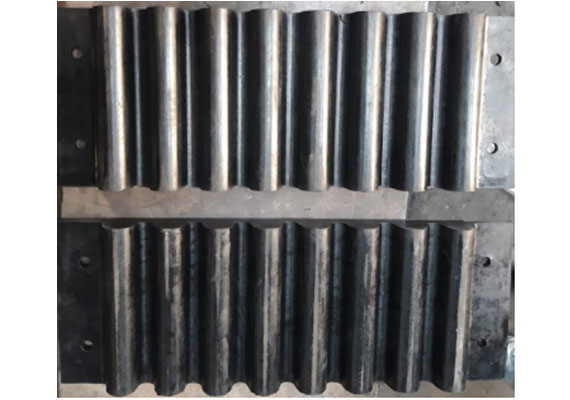

Wear Bars

Our wear bars (also known as lifter bars) are used for grinding mills as stock items. These bars comprise of aluminium T bolt profile and wear resistant rubber. The aluminium profile vulcanized into the bar allows fast and easy installation due to the T-bolt fastening system.

Wear bars are excellent wear lining to; washing drums, rock boxes, feed cone-crushers and other applications subject to wear and noise.

The standard length available is 1520mm, in thicknesses ranging from 75mm to 150mm.